- The difference between high-voltage light strips and low-voltage light strips

The voltage used by high-voltage light strips is generally 220V and can be directly connected to the household power supply, while low-voltage light strips usually use 12V or 24V DC. Therefore, high-voltage light strips require a special switch to control the current, while low-voltage light strips require an adapter to convert the voltage to 12V or 24V DC.

The difference between low-voltage light strips and high-voltage light strips

- Different specifications and lengths

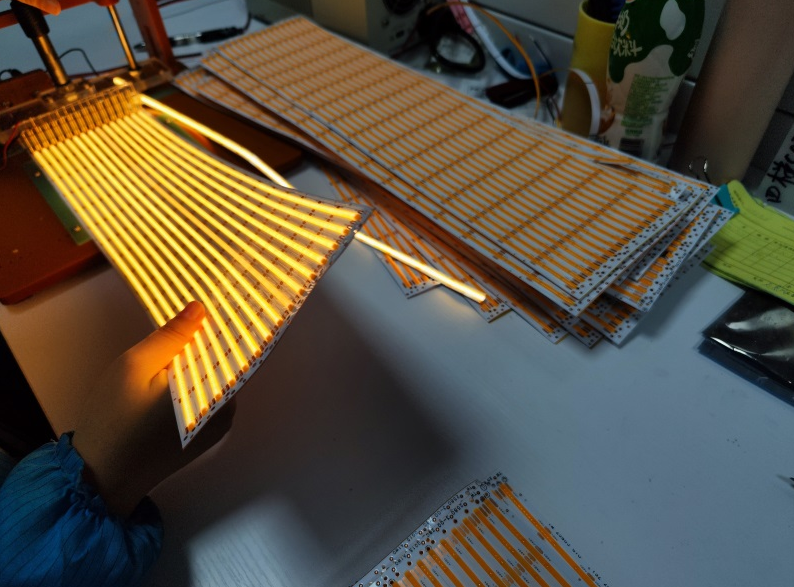

The most common type of low-voltage light strip is 12V and 24V. Some low-voltage lamps have plastic protective covers, while others do not. The protective cover is not to prevent electric shock (low voltage is relatively safe), but the usage requirements are slightly different. For example, top-lit cloth lamps are prone to dust and dust accumulation, and more It is recommended to use one with a protective cover for easy cleaning.

Because the substrate of low-voltage light strips is relatively thin and the ability to overcurrent is relatively weak, most low-voltage light strips are 5m long. If the usage scenario requires a long light strip, multiple wiring locations and multiple drivers will be needed. In addition, there are also 20m strips, and the substrate of the light strip is made thicker to increase the current carrying capacity.

Most high-voltage light strips are 220V, and the length of high-voltage light strips can be continuous up to 100m. Relatively speaking, the power of high-voltage lamp strips will be relatively high, and some can reach 1000 lm or even 1500 lm per meter.

What is the difference between low-voltage light strips and high-voltage light strips?

- Cutting lengths vary

When the low-voltage light strip needs to be cut, check the cutting opening mark on the surface. There is a scissor logo on every short section of the low-voltage light strip, indicating that this place can be cut.How often should the length be cut? It depends on the working voltage of the light strip.

For example, a 24V light strip has six beads and one scissor opening. Generally, the length of each section is 10cm. Like some 12V, there are 3 beads per cut, about 5cm.

High-voltage light strips are generally cut every 1m or even every 2m. Remember not to cut from the middle (it needs to be cut across the whole meter), otherwise the entire set of lights will not light up. Suppose we only need 2.5m of light strip, what should we do? Cut it out to 3m, and then fold the excess half meter back, or wrap it with black tape to prevent light leakage and avoid local over-brightness.

What is the difference between low-voltage light strips and high-voltage light strips?

- Different application scenarios

Because the low-voltage flexible light strip is very convenient to use, after tearing off the protective paper from the adhesive backing, you can stick it in a relatively narrow place, such as bookcases, showcases, kitchens, etc. The shape can be changed, such as turning, arcing, etc.

High-voltage light strips are generally equipped with buckles for fixed installation. Since the entire lamp has a 220V high voltage, it would be more dangerous if the high-voltage lamp strip is used in places that can be easily touched, such as steps and guardrails. Therefore, it is recommended that high-voltage light strips be used in places that are relatively high and cannot be touched by people, such as ceiling light troughs. Pay attention to the use of high-voltage light strips with protective covers.

What is the difference between low-voltage light strips and high-voltage light strips?

- Driver selection

When installing the low-voltage light strip, the DC power driver must be installed in advance. After the DC power driver is installed, it must be debugged until the debugged voltage is consistent with the requirements of the low-voltage light strip before it can be used. This requires special attention. a little.

Generally, high-voltage light strips have strobes, so you must choose a suitable driver. It can be driven by a high-voltage driver. Generally, it can be configured directly in the factory. It can work normally when connected to a 220-volt power supply.

- How to distinguish between high-voltage light strips and low-voltage light strips

- Check the voltage label: The voltage of high-voltage lamp strips is generally 220V, and the diameter of the power cord is thicker; while the voltage of low-voltage lamp strips is generally 12V or 24V, and the power cord is thinner.

- Observe the controller: High-voltage light strips require a special switch to control the current; low-voltage light strips require an adapter to convert the voltage to 12V or 24V DC.

- Check the power supply: High-voltage light strips can generally be plugged directly into the household power supply, while low-voltage light strips require an adapter to convert the power supply to 12V or 24V DC.

- Measure the voltage: You can use a multimeter and other tools to measure the voltage. If the voltage is 220V, it is a high-voltage light strip; if the voltage is 12V or 24V, it is a low-voltage light strip.

In short, distinguishing between high-voltage light strips and low-voltage light strips can be judged from multiple dimensions such as voltage identification, controller, power supply and voltage. When purchasing a light strip, you must choose a suitable light strip according to the usage scenario and needs to ensure the safety and stability of use.